V-rings (also known as V-seals) are all-rubber

seals that are installed directly onto a

shaft to seal against a housing face, a bearing, or

the back of a

shaft seal. Offering simplicity and versatility,

V-rings are chiefly used to protect bearings or other

parts from contamination, as well as to retain grease.

V-rings can also function effectively in dry

applications with very low torque.

V-ring consists of three parts: a body, a conical

self-adjusting lip, and a hinge. In service, the

elastic body of the seal rotates with the shaft

while the adjustable lip maintains a

dynamic seal in axial contact with a perpendicular

counter face. V-rings offer many advantages. V-ring

tolerates greater radial variation than a traditional

shaft seal. V-ring also tolerates greater

shaft-to-bore misalignment (STBM). A V-ring also

tolerates greater

dynamic run-out (DRO) than a standard shaft seal.

And a V-ring can function as both a seal and a

slinger. V-rings are also less expensive than

traditional shaft seals.

Another important advantage of the V-ring is its

elasticity. A V-ring can be stretched during

installation onto a shaft without disassembly of the

unit, and one size V-ring can be used on a range of

shaft sizes in either metric or English dimensions. A

commonly used V-ring material is wear-resistant

nitrile (-40° F to 225° F). V-rings made of

fluoroelastomers are typical in

applications with higher temperatures (-20° F to 300°

F).

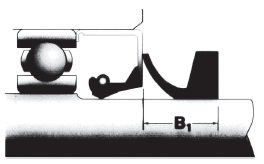

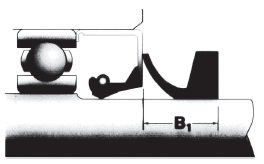

V-rings are often used as supplemental seals in

conjunction with traditional shaft seals. Studies have

shown that a V-ring paired with a

single lip shaft seal excludes contaminants better

than a shaft seal with a conventional

radial dirt lip.

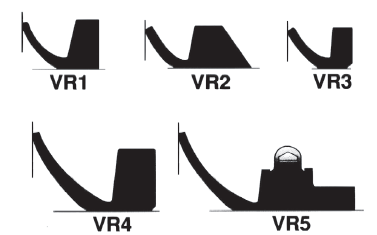

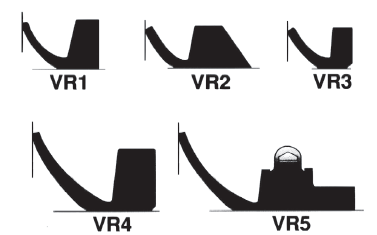

V-rings profile types: